Power For Brighter Future

Products we use to build future with green energy

Motor Control Center Panel

These usually comprise of incoming Air circuit breakers, main horizontal and vertical bus bars, outgoing starter modules with MCCB / Switch fuse unit, overload relays, contractors, etc. With adequate space for connection of cable and are easily extendable on either side and have excellent short circuit with stand performance of bus bar comprised of bolted / riveted modular construction.

Key feature of motor control centers offered by Voltaic:

- Rated up to 6000A.

- Rated operating voltage up to 690V.

- Tailored control using VFD, soft starter & DOL.

- Ample cabling space for easy connections.

- Top and bottom cable entry.

- Panels for front or rear access to suit application.

- Index of protection: IP 54.

- Floor mounting.

- Maximum safety & reliability.

- Modular system with customized design to meet end user requirements.

Main Distribution Board

Power Distribution is a system, consisting of a Main Distribution Board (MDB), Sub Main Distribution Boards (SMDBs) and Final Distribution Boards, by which the electrical energy is transmitted via branches to reach the exact end user. An MDB is a panel or enclosure that houses the fuses, circuit breakers and ground leakage protection units where the electrical energy, which is used to distribute electrical power to numerous individual circuits or consumer points, is taken in from the transformer or an upstream panel. An MDB typically has a single or multiple incoming power sources and includes main circuit breakers and residual current or earth leakage protection devices. A MDB is comprised of a free standing enclosure, a bus bar system, MCCB's, metering and support equipment’s and required current transformers. Panels are assembled in a systematic manner such as incomer section and outgoing section.

Key feature of main distribution board offered by Voltaic:

- Rated up to 6000A.

- Rated operating voltage up to 690V.

- Ample cabling space for easy connections.

- Top and bottom cable entry.

- Panel for front or rear access to auto application.

- Index of protection: IP 54 & Floor Mounting.

- Maximum safety and reliability.

- Module system with customized design to meet end user requirement.

Generator Control &

Synchronization Panel

Synchronizing panel will operate on an automatic mains failure system, so that when the main supply is interrupted on one or all phases (after an adjustable delay period) the generator setup will start together. After an initial warm up period (adjustable) the generators will synchronize with each other by means of motorized circuit breakers or contactors onto a common bus bar. Next, the motorized change-over switch will be closed and the load will be connected to the main distribution box.The load share units continuously monitor the load and during low demand periods one or two generators will be shut down to save on fuel consumption. As demand rises again the second generator and third generator will be restarted, synchronized and reconnected to the load. When the AMF control unit detects that the main supply has been restored an adjustable observation period is activated before the main supply is reconnected. A cool down period will then follow, after which the generator sets will be shut down.

Key features of General Control & Synchronization Panel:

- 3-pole or 4 -pole system as required.

- Protection class up to IP 54.

- Load sharing/load shedding.

- Automatic and manual synchronizing.

- Factory built to client's specifications.

- Ratings up to 6000A.

- Control functions available for engine monitoring, warm up and cool down periods, emergency shut down, multi attempt engine start control, engine test runs.

Automatic Transfer Switch or

Automatic Main Failure Panels

Automatic Transfer Switch (ATS) is an automated switching device that transfers load power to backup power during mains failure and back to its original state when mains power reinstates to the normal condition. It will have its own contacts, microprocessor to analyses the conditions whether power supply is normal or backup and need backup or mains power. Here "backup power" may become either standby generator or another mains power or static power source like UPS.

Included Components & Functions With ATS / AMF:

- Full Relay Protection for 3 Ph-, 4 wire System. Transfer to emergency source when voltage on any phase drops to 70 percent or less. Retransfer to normal when all phase voltages are 90 percent or more.

- Adjustable time delay on generator start sequence, 10 seconds maximum, in all second intervals.Adjustable time delay on automatic transfer to normal, 15 to 30 minutes in 1-minute intervals. If the emergency source fails and power is available from the normal source, the time delay shall be defeated and the transfer operation immediately initiated.

- Two normally open and two normally closed auxiliary contacts on main shaft.

- Mounted pilot light to indicate switch in normal position.

- Mounted pilot light to indicate switch in emergency position.

- Engine Starting Contacts.

- Test switch and necessary equipment for remote test switch.

- Under -frequency Relay.

- Other Controls as necessary for the smooth automatic functions of the system.

Capacitor Bank (PFI Panel)

Capacitor Bank improve the power factor by adding capacitive reactance in steps as per the power factor requirement.

Power factor controller constantly monitors the load (and power factor) of the system on LV Panel and switch on/ off the capacitor steps to maintain the system power factor to the set value. It provides optimum power factor improvement to compensate for lagging Vars in the system, seen as a clean and reliable solution to providing quality power to the distribution network and to economize the electricity charge to customer/consumer.

Key features of Capacitor Banks offered by Voltaic:

- Rated up to 700kVAR.

- Power factor correction by multi step design.

- Standard & detuned capacitor banks.

- Capacitors are Self -healing, pressure sensitive disconnect or & fitted with discharge resistors.

- Detuned reactor tuning order 2.7 (135 Hz), 3.8 (190 Hz) and 4.3 (215 Hz).

- Microprocessor based power factor controller with various switching sequences.

- Special contactors for power factor correction capacitors; equipped with limiting resistance for the inrush current.

- Easy installation & maintenance.

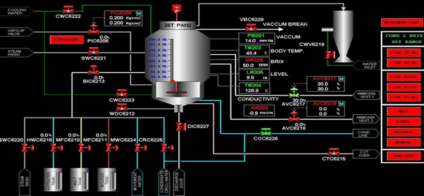

Process Automation

BOILER AUTOMATION

We have full grip on Boiler Automation with O2 trimming base electronic curve PLC System on any kind of Boiler like Package Type, Water Tube, Fire Tube, Thermo Oil and Coal etc. We also have expertise of Steam, Gas and Water online Flow Metering system. Package Type & Coal Boiler

MACHINE AUTOMATION

We have done multiple projects in Pharmaceutical Industries of different machine like Blow, Fill & Seal machine, Blow Molding Machines, Sterilization or Auto Clave Plant and Distillation Plant etc.